Electrification - Can the Grid Cope

- Details

- Written by: J C Burke

- Category: Grid Resilience

- Hits: 332

Summary: "Electrification - Can the Grid Cope?"

Summary: "Electrification - Can the Grid Cope?"

SOURCE DOCUMENT: Watt-Logic - @KathrynPorter26 (on X/Twitter

Our Summary: so close to our own conclusions over the last few years - a great warning - but who is listening???

Core Thesis: The UK's aggressive electrification plans for heating, transport, and industry are fundamentally unrealistic and risk causing grid failures before 2030. The nation faces a dangerous mismatch between ambitious targets and practical delivery capabilities.

Key Findings:

Demand Projections:

- Electrification could add 7-10 GW by 2030

- AI data centres add another 6 GW

- Total: up to 15 GW of new demand by 2030

- Yet existing demand may require rationing even without this growth

The Triple Crisis:

- Supply Crisis: Ageing gas and nuclear plants retiring faster than firm replacement capacity can be built. Wind/solar cannot provide dispatchable power needed for reliability.

- Deployment Stalling: Heat pumps, EVs, and industrial fuel-switching are all falling behind targets despite government pressure.

- Infrastructure Crisis: Gas network deterioration threatens backup power supplies. Distribution grids can't handle local electrification loads.

Reality Check on Targets:

Care Homes UK Project

- Details

- Written by: J C Burke

- Category: PROJECTS & INVESTMENT

- Hits: 155

UPDATE 29th December 2025

UPDATE 29th December 2025

Given the implications of the Japanese policy reversal (ending of the "Carry Trade Era" - 0n 19th December 2025) - The Japan liquidity withdrawal is a real macro risk, but care homes offer one of the best risk-adjusted opportunities precisely because demand is structural and counter-cyclical. Use the next 6-12 months to prepare for opportunistic acquisition, rather than avoiding the sector entirely.

Given the above caveat, our investor pitch still stands - for purpose-built care and nursing homes in the UK, reimagined as self-sustaining micro-cities, incorporating Combined Heat, Power, and Cooling (CHP+C), active landscaping, and earthworks. The financial projections and market data have been revised to reflect the latest available information as of 4th November 2025, using insights from recent sources and adjusting for inflation, market trends, and economic conditions. The structure remains investor-focused, emphasizing sustainability, profitability, and alignment with the UK’s elderly care needs

Care Home Investment Opportunity

Executive Summary

Purpose-Built Care and Nursing Homes as Self-Sustaining ‘Micro-Cities’ in the UK

Investment Opportunity

- Market Context: UK care home market valued at £26.2bn (December 2024), with 50% of homes in unsuitable converted properties struggling with rising costs

- Core Strategy: Acquire older care homes at £2.5m each, redevelop into 75-bed luxury facilities for £6-7m, achieving valuations of £8-15m

- Timeline: 3-year project with potential £150m exit or long-term lease revenue strategy

- Market Growth: 2024-2025 marked as "year of growth" with improved occupancy levels and increased transactional activity

Current Market Performance (2025)

- Occupancy Rates: 89.6% occupancy in Q1 2025, stable from 2024 levels

- Average Weekly Fees: £1,260 AWF in Q1 2025, representing 7.9% year-over-year increase

- Market Size: £9.3bn market size in 2025 for residential nursing care

- Demographic Demand: Need for 440,000 additional care home beds by 2032 to reduce over-80s to care home bed ratio from 7.45:1 to 5:1

Financial Projections

Acquisition Plan: 16 properties over 24 months with revolving bank financing

Revenue Options:

- Sales: £300,000-£360,000 per bed depending on quality and location (2024 completed transactions)

- Premium Valuations: £100,000-£200,000 per bed for high-spec facilities (£7.5m-£15m per 75-bed home)

- Leasing: £540,000-£720,000 annual rent per property (5-7% yield)

- EBITDA Multiples: Currently 4-10x for freehold properties, reduced by at least 2x for leased

- Construction Costs: £7-12m for 60-80 bed facility in 2025, with costs £2,000-£3,500+ per square metre

Energy Cost Challenge & Solution

The Elephant in the Energy Centre

- Details

- Written by: J C Burke

- Category: UK Case Studies

- Hits: 226

Manchester's CHP Paradox

EXECUTIVE SUMMARY

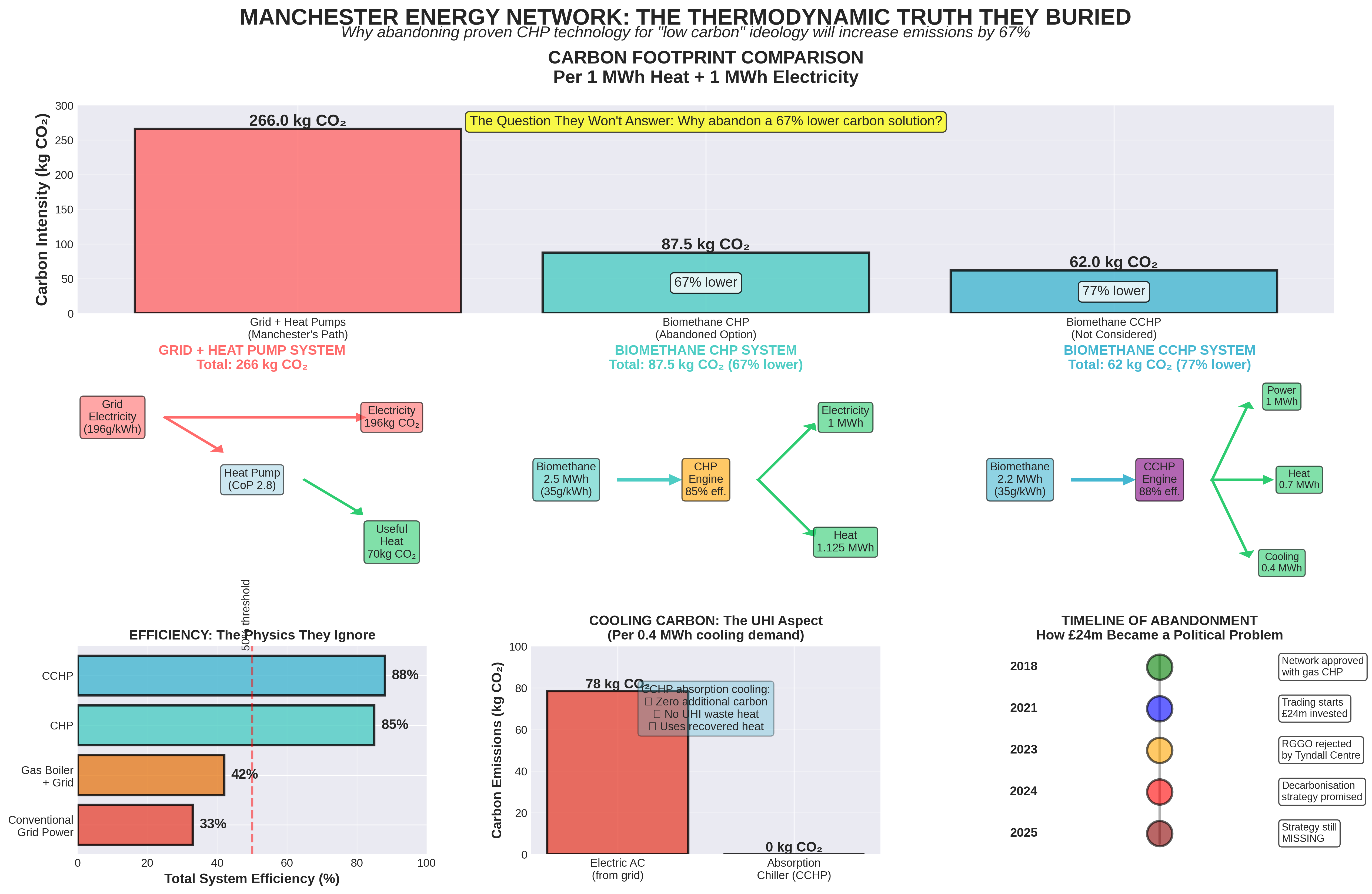

Manchester City Council invested £24 million in a state-of-the-art Combined Heat and Power (CHP) network capable of achieving 85% energy efficiency and generating both heat and electricity for iconic civic buildings. Three years later, despite mounting financial losses of £1.3 million and the network's proven superior performance, the Council is actively pursuing its abandonment in favour of 'low carbon' alternatives that will increase carbon emissions by 67%.

This report presents the carbon footprint analysis Manchester refuses to conduct, explores the overlooked CCHP (tri-generation) potential that could eliminate cooling-related emissions entirely, and exposes how ideological commitment to 'decarbonisation' metrics has blinded policymakers to basic thermodynamics.

We have coined a new 'term' "Carbon (dioxide) Prejudice" - when discounting alternatives, nor doing the analysis - if Methane is involved

The Conservation of Energy

- Details

- Written by: J C Burke

- Category: ENERGY POLICY

- Hits: 168

Based on the NESO report released yesterday (26th November 2025 - hidden behind the Budget fiasco??) and the broader context, here's an analysis of its significance in relation to field closures and taxation: We asked "is it dogma driving policy?"

Based on the NESO report released yesterday (26th November 2025 - hidden behind the Budget fiasco??) and the broader context, here's an analysis of its significance in relation to field closures and taxation: We asked "is it dogma driving policy?"

Preamble:

"We are all missing the fundamental point: We're wasting 40-60% of energy through inefficiency."

Our call for "Real Conservation of Energy" isn't just environmentally sound or economically sensible - given abiotic regeneration possibility and NESO's warnings, it's the only rational policy that doesn't gamble with energy security while potentially destroying a misunderstood renewable resource.

The NESO Report's Key Findings

NESO warns that UK gas availability is projected to fall by 78% by 2035 compared to current levels, dropping from 24.5 billion cubic metres this year to just 5.4 billion cubic metres by 2035. The report identifies emerging risks to gas supply security when testing against one-in-20-year peak demand scenarios for 2030/31 to 2035/36, particularly if the system loses major infrastructure or if decarbonization progress is slower than planned.

The Taxation Context

The timing of this warning is particularly significant given the government's recent tax changes. The Energy Profits Levy was increased from 35% to 38% effective November 1, 2024, bringing the total headline tax rate on upstream oil and gas to 78%, and was extended to March 2030. Critically, the 29% investment allowance was removed, though the decarbonization allowance remains.

The Connection Between Taxation and Declining Production

The industry argues there's a direct link between the tax regime and accelerating decline:

- No new exploration wells have been drilled in 2025, and domestic oil and gas production has fallen by 40% in the last five years and is on course to halve again by 2030

- Industry modeling shows that without fiscal reform, oil and gas production will fall by approximately 40% from 2025 levels within the next five years

- The Energy Profits Levy has resulted in an increase in decisions to cease production, leading to higher decommissioning costs in the short term

The Decommissioning Acceleration

Annual decommissioning expenditure in the UK Continental Shelf surpassed £2 billion for the first time in 2024, accounting for 15% of total oil and gas expenditure, with projections indicating this share may double and exceed 30% by the end of the decade. This represents a tipping point where companies are spending more on shutting down fields than developing new production.

UHI Effect in London

- Details

- Written by: J C Burke

- Category: Urban Heat Island

- Hits: 743

The Urban Heat Island Effect in London:

Implications for Energy Policy & the Case for Combined Cooling, Heat & Power via Bio-Methane

Executive Summary

"London faces a significant and worsening Urban Heat Island (UHI) challenge that current policy approaches are failing to address adequately." The city centre can be up to 10°C warmer than surrounding rural areas, with this differential intensifying at night when buildings release stored heat. This phenomenon directly increases cooling energy demand, creates a self-reinforcing feedback loop through air conditioning waste heat, and imposes substantial health and economic costs—estimated at £453-987 million annually from heat-related mortality alone.

Current policy prioritises carbon metrics over thermodynamic efficiency, inadvertently discouraging solutions that could address both objectives simultaneously. Combined Cooling, Heat and Power (CCHP) systems fuelled by bio-methane offer a technically superior and policy-coherent solution that:

- Achieves 80-90% energy utilisation versus 40-50% from conventional generation

- Captures waste heat for district heating rather than rejecting it to exacerbate the UHI

- Provides cooling through absorption chillers that do not add heat to the urban environment

- Uses renewable bio-methane with negative lifecycle carbon emissions

- Integrates waste management with energy production in a circular economy model

This section presents the scientific evidence for London's UHI problem and demonstrates how CCHP via bio-methane represents a thermodynamically sound, carbon-neutral, and economically viable solution that current regulatory frameworks inexplicably discourage.

Page 2 of 11