AI and EV Infrastructure Needs

- Details

- Written by: J C Burke

- Category: Grid Resilience

- Hits: 7289

Further "interviews" with ChatGPT the {claimed} "AI" resource; a series of questions are needed to get to the issues, like any interview.

ZES/SEE Interviewer Questions, commentary and/or reaction to ChatGPT replies

"Is google search banning websites or pages? Is google search also filtering access to websites or platforms which do not subscribe to the climate emergency agenda?"

ChatGPT Replied

As of my last knowledge update in September 2021, Google Search does not ban websites or pages based on their stance on the climate emergency or any particular agenda. Google Search primarily ranks web pages based on their relevance and the quality of their content, using algorithms designed to provide users with the most useful and informative search results.

Google does have policies regarding the removal of websites or pages that violate its guidelines, such as those involving illegal content, malware, or other forms of harmful or deceptive content. However, these guidelines do not include filtering or banning websites or pages based on their views on specific political or environmental issues, including the climate emergency.

It's important to note that search engine algorithms can change over time, and Google's policies may have evolved since my last update. For the most up-to-date information on Google's search policies and practices, I recommend checking Google's official documentation or news from reputable sources.

ZES/SEE Interviewer Questions, commentray and/or reaction to ChatGPT replies

"Such a pity you can only confirm your answer as at September 2021 - 2 years ago!"

ChatGPT Replied

I understand your concern about the knowledge cut-off date, and I apologize for any inconvenience it may cause. My training data only goes up until September 2021, so I can provide information based on that knowledge. However, I encourage you to verify the most current information by checking Google's official statements, policies, and recent news updates, as the internet landscape and policies can change over time. If you have any specific questions or need information on a different topic, please feel free to ask, and I'll do my best to provide useful answers.

ZES/SEE Interviewer Questions, commentary and/or reaction to ChatGPT replies

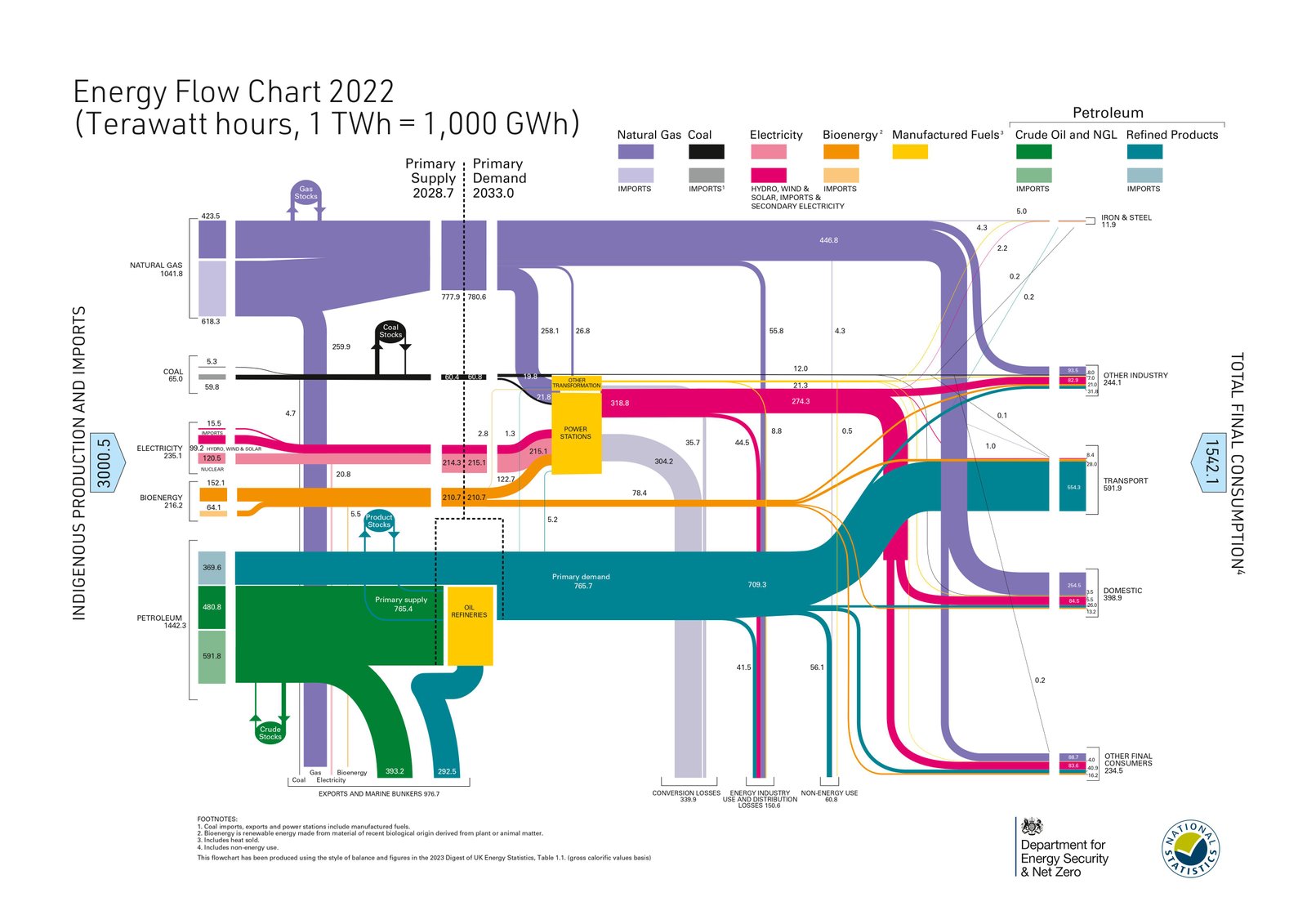

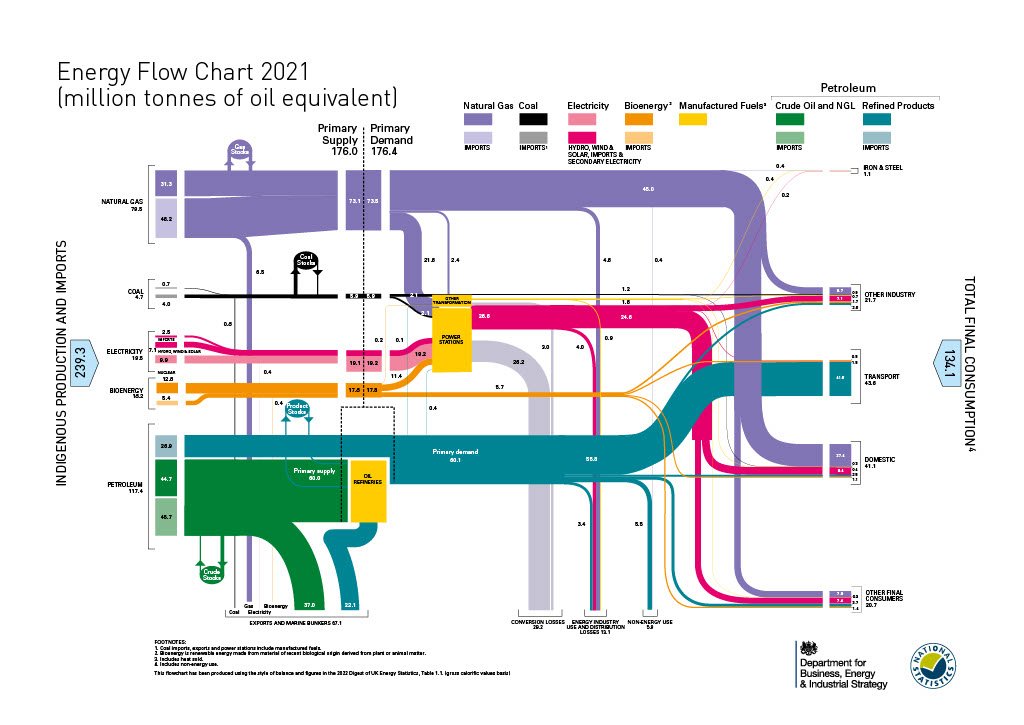

"In the United Kingdom and given the policy to ban ICE vehicles and replace them with EV by 2030 or 2035, how is the UK Electricity generation, supply and local distribution going to cope with the massive demand. Given also the move from gas heating to Electric Heat Pump over the same period, what will the Central Generators have to target between now than then to meet this increased power demand?"

ChatGPT Replied

The United Kingdom's transition from internal combustion engine (ICE) vehicles to electric vehicles (EVs) and the shift from gas heating to electric heat pumps will indeed lead to increased demand on the electricity generation, supply, and distribution infrastructure. To meet this increased power demand and ensure a smooth transition, several key strategies and targets have been put in place:

- Renewable Energy Expansion: The UK government has set ambitious targets to increase the share of renewable energy in the electricity generation mix. This includes expanding wind power, solar power, and other forms of renewable energy. Offshore wind farms, in particular, are expected to play a significant role in meeting the increased demand for electricity.

- Nuclear Energy: Nuclear power also remains a part of the UK's energy strategy. While some older nuclear plants are being decommissioned, new ones are planned to help provide a stable source of low-carbon electricity.

- Grid Infrastructure: Upgrading and expanding the electricity grid infrastructure is crucial to accommodate the increased demand and to ensure that power generated from renewable sources can be efficiently distributed to where it's needed. This includes the development of smart grids and grid-scale energy storage solutions.

- Electricity Storage: The UK is investing in energy storage technologies such as batteries to store excess electricity generated during periods of high renewable output and release it when demand is high. This helps to stabilize the grid and ensure a continuous power supply.

- Demand-Side Management: Encouraging demand-side management practices, such as time-of-use pricing and incentives for EV owners to charge during off-peak hours, can help balance electricity demand and reduce the need for additional capacity.

- Efficiency Measures: Implementing energy efficiency measures in homes and businesses, including the installation of more energy-efficient appliances and buildings, can help reduce overall electricity consumption.

- Research and Innovation: Continued research and innovation in energy technology are essential for finding more efficient and sustainable ways to generate and use electricity.

The exact targets and strategies may vary over time and can depend on government policies and market developments. The transition to electric vehicles and electric heating is a significant undertaking, and careful planning is required to ensure a reliable and sustainable electricity supply throughout this transition.

It's worth noting that meeting these targets will require collaboration between the government, energy companies, and consumers to achieve a successful transition to a low-carbon, high-electricity-demand future. Additionally, periodic reviews and adjustments to energy policies and infrastructure plans will likely be necessary to address evolving challenges and opportunities.

Net Zero - They Do Not Have A Clue

- Details

- Written by: J C Burke

- Category: Net Zero Critique

- Hits: 66943

Spending watchdog MPs on the Public Accounts Committee are concerned about lack of transparency, [and] about the cost to consumers of the Government’s plan to expand nuclear, solar and wind power.

Spending watchdog MPs on the Public Accounts Committee are concerned about lack of transparency, [and] about the cost to consumers of the Government’s plan to expand nuclear, solar and wind power.

In addition, the focus on "Carbon Capture Measures" are particularly worrying, from both a cost and desirability aspect, as it blindly accepts the premise that CO2 is a "Causation" of; Global Warming {?} or now "Climate Change". No latitude is given any any dissenting viewpoints such as Dr. Patrick Moore Lee Yun-Jeong Dr Richard Lindzen, even David Ballamy - In 2008 Bellamy signed the Manhattan Declaration, calling for the immediate halt to any tax-funded attempts to counteract climate change. He maintained a view that man-made climate change is "poppycock", insisting that climate change is part of a natural cycle!

In addition Energy Efficiency improvements both in buildings and in the Centralised Electricity systems are not given sufficient prominence - a tragedy considering their "low hanging fruit" aspects and inexpensive improvements. Particularly in the UK's Housing Stock {24.2 million} and the problems with building so few new {and highly energy efficient} properties. New Build Completions; 204,530 {to March 2022} AND 210,320 {to March 2023} and 6 months to September 2023 of 93,480 Completions - and much fewer starts due to Covid Lockdown {insanity}} [Housing, Commercial Retail and Industrial].

The Government estimates that up to £400 billion of public and private investment in new generating capacity will be needed by 2037, but the PAC is unconvinced that the private sector has been given enough clarity to confidently invest.

In a critical report published below {on 15th June 2023}, the PAC calls on Government to pull together numerous decarbonisation plans into coherent strategy. This should be pulled together by autumn 2023 at the latest.

The Government’s delivery plan must also set out when and how the costs of decarbonising the power sector will be likely to have an impact on energy bill payers and taxpayers.

Dame Meg Hillier MP, Chair of the Committee, said: “What is the plan? It has now long been understood and accepted that greening our economy is an existential priority, with the Government setting itself the target of securing an entirely low-carbon power supply by 2035.

- “But without a coherent delivery plan to get there, the Government will find it harder to know what decisions it must take, and when, to ensure that it can realistically reach its ambitions.

- “There are just twelve years left for the Government to meet its low carbon energy target, and much still to do if this is to be achieved – and at a cost the taxpayers and bill payers can bear while ensuring the lights stay on.

- “There is an information vacuum in key areas – energy efficiency, investment, the cost of the transition to the public – that must be addressed.

- “We need an overarching plan charting the way, to provide much-needed confidence to the businesses and consumers who are needed to deliver it. When it comes to tackling the climate crisis, we can see around us, we are already living on borrowed time.”

Actual Discussion and oral Evidence: On following pages

Recycling Plastic Waste

- Details

- Written by: J C Burke

- Category: Technical Papers

- Hits: 8057

Plastic packaging, films, and assorted plastic components will need careful attention to best use this waste stream to the greatest effect. Consequently incineration is not considered a viable solution due to problems with dioxins in the pollutant exhaust and poor levels of energy release.

However many plastics are able to be re-formed into useful objects, in the storm water and management of flooding in many situations. One such use is of stable, underground water storage, both as flood control and for retention in hot climates - but suffering from short periods of heavy rains.

However many plastics are able to be re-formed into useful objects, in the storm water and management of flooding in many situations. One such use is of stable, underground water storage, both as flood control and for retention in hot climates - but suffering from short periods of heavy rains.

These interlocking forms can be stacked underground up to 5m in height - and still allow the land above to be used as playing fields or even for parking with appropriate additional strengthening. Very much ideal for nations where water/rainfall is for limited periodicity but heavy. Example West Coast of the African Continent, with trade winds bringing heavy rains.

Stackable Plastic Crates

Stackable stormwater control crates offer a modular design that give you more flexibility over how the system is installed and set-up in the ground. One of the major benefits of using stackable crates is that the installation can be completed much faster and without the need to use specialist heavy equipment. These types of crates are more suitable for areas that cannot accommodate a long row of crates attached to each other. Instead, they are stacked on top of each other to retain a large storage holding and facilitate the release of rainwater into the surrounding environment when needed.

Light duty crates

Light duty stormwater control crates are best suited for pedestrian loads through to domestic vehicular loads. In most cases, light duty crates are installed in gardens and landscaping areas and have a load limit of around 20 tonnes. The depth of cover, tank depth, top surface cover, ground type (granular or cohesive) and usual loading traffic will all have to be accounted for to ensure this type of crate is suitable for the land.

Heavy duty crates

Heavy duty stormwater control crates are designed to accept large weight loads at ground level, often exceeding a 60-70 tonne load rating. The exact load a capacity is decided by the cover depth, soil type, surface finish and other similar factors, which can be determined by the installation company. A heavy-duty stormwater control crate is typically installed in areas that experience large amounts of traffic on a regular basis, or for car parking areas that accommodate several domestic vehicles.

Energy from Waste

- Details

- Written by: J C Burke

- Category: Biomethane CHP

- Hits: 7777

Key Situations:

Outline of the waste streams available that could be used for energy production - ideally bio-methane. However, plastics are today's "pollutants" to the viability of waste streams to energy. The plastic need a different method of treatment. Overall, we wish to avoid the less efficient {and problematic emissions} of incineration technologies.

WORK IN PROGRESS:

TYPES OF WASTE STREAMS |

|

|

|

Homogeneous Organic Wastes, typically farming wastesThese typically farm based bio-digesters, can create good volumes of bio-methane [with some CO2 and other contaminants - which can be removed] from a wide variety of soft organic wastes - from cattle slurry to oil-rich seeds. We have a database of the energy values of most farm wastes to be able to estimate economic viabilities in terms of exporting to the gas grid, generating electricity and exporting to the electric grid or even as transport fuels {compressed natural gas} CNG. |

|

|

|

Palm Oil Wastes and other industrial processesIn regions where Palm Oil production is prevalent, the waste lagoons associated with Palm Oil production, with the husks etc can be utilitise as rich source of bio-methane. The waste from these processes can be problematic in environmental terms - so bio-digestion is an ideal transformation into a commercial fuel or used in energy and heat production as a feed back into the industrial process itself. |

|

|

|

Mixed Wastes and Rubbish TipsThere are a great many pre-existing waste tips of varying sizes and "conditions" globally - [Some tips can be on-fire or explosive with the methane generation]. Comprehensive treatment and separation of the leachate and methane can produce vast quantities of bio-methane [again with CO2, H2S etc - all of which can be separated]. The Leachate is also rich in Ammonia and other compounds. Experience in the UK shows that a waste tip can produce methane [and other smaller impurities] for up to 30 years. The London Brick Works in Bedfordshire used bio-methane from the waste tip on their clay pits {as supplied from London}, to fire their brick kilns for decades. |

|

|

|

Plastic Waste "Pollution"The vastly increased usage of plastics over the last decades, has changed the composition of waste globally. Plastic themselves are difficult {not impossible} to break down and thus make bio-digestion more difficult. In practice the separation of Plastic {and metals, builders rubble etc} needs to be carried out before digestion. Other technologies to deal with plastics {see below} like Cold Plasma Pyrolysis can yield methane and Hydrogen. |

Anaerobic digestion can be used to generate energy from organic waste like food and animal products. In an oxygen-free tank, this material is broken down to biogas and fertiliser.

It’s an approach with big potential. If we treated 5.5 million tonnes of food waste this way, we’d generate enough energy to serve around 164,000 households while saving between 0.22 and 0.35 million tonnes of CO2, in comparison to composting.

Extracting the biogas produced by biodegrading materials on landfill sites is another way of getting useful energy from waste. Although it’s an approach that’s in decline due to the reduction of the amount of organic matter going to landfill, it’s making a notable contribution to UK energy supply: the source 3.04TWh of green electricity in the last year, in fact.

Tackling the plastic problem

Plastic waste has risen to significant levels of public consciousness in recent years, for its negative impact on habitats and species. In response, the UK Government’s 25-year Environment Plan pledges to eliminate all ‘avoidable’ plastic waste by the end of 2042 – and it’s not alone in making such political commitments. Can waste-to-energy step in here?

Converting plastic waste to energy certain makes sense from a chemical perspective, given plastics come from the same origin as fossil fuels. We’ve already looked at the two main techniques involved: pyrolysis, where plastic is heated in the absence of oxygen, and gasification, where air or steam heats the waste, creating gases that either produce petrol or diesel, or are burned to generate electricity.

New techniques such as cold plasma pyrolysis, provide the potential to create fuels such as hydrogen and methane, as well as useful chemicals for industry.

But there are barriers in the way of wider uptake of plastic-to-energy techniques. Gasification of plastics requires significant investment, including advanced controls and pre-treatment facilities. Also, developing plastic-recycling plants presents a risk of limiting those facilities, when decision-makers may instinctively opt for waste strategies where general waste is processed together, rather than separating out different elements.

Novel approaches to waste management in the UK will surely rise in the coming years. Recycling rates seem to be plateauing, with minor increases only seen. While generating energy from waste has a lot of promise, we need to focus on making products last longer, and when they really can’t be fixed, finding ways to recycle and reuse them. Only when those options are exhausted should we turn to waste-to-energy.

the prospect of using rubbish for fuel isn’t too far from reality. Plastics, in particular, contain mainly carbon and hydrogen, with similar energy content to conventional fuels such as diesel.

Plastics are among the most valuable waste materials – although with the way people discard them, you probably wouldn’t know it. It’s possible to convert all plastics directly into useful forms of energy and chemicals for industry, using a process called “cold plasma pyrolysis”.

Pyrolysis is a method of heating, which decomposes organic materials at temperatures between 400℃ and 650℃, in an environment with limited oxygen. Pyrolysis is normally used to generate energy in the form of heat, electricity or fuels, but it could be even more beneficial if cold plasma was incorporated into the process, to help recover other chemicals and materials.

The case for cold plasma pyrolysis

Cold plasma pyrolysis makes it possible to convert waste plastics into hydrogen, methane and ethylene. Both hydrogen and methane can be used as clean fuels, since they only produce minimal amounts of harmful compounds such as soot, un-burnt hydrocarbons and carbon dioxide (CO₂). And ethylene is the basic building block of most plastics used around the world today.

As it stands, 40% of waste plastic products in the US and 31% in the EU are sent to landfill. Plastic waste also makes up 10% to 13% of municipal solid waste. This wastage has huge detrimental impacts on oceans and other ecosystems.

Interview with AI Chat Bot

- Details

- Written by: J C Burke

- Category: UK Energy Security

- Hits: 9775

A discussion regarding electricity production and energy efficiencies {mainly UK, but some USA}. AI is starting to learn - but needs to watch out for "settled-science" {an oxymoron} and the volume of material covering the "conventional wisdom." We have also added some additional commentary to help the {Child} AI as it learns, and to assist it to innovate, if this is possible.

A discussion regarding electricity production and energy efficiencies {mainly UK, but some USA}. AI is starting to learn - but needs to watch out for "settled-science" {an oxymoron} and the volume of material covering the "conventional wisdom." We have also added some additional commentary to help the {Child} AI as it learns, and to assist it to innovate, if this is possible.

Here are the questions asked of ChatGBT, and its corresponding answers. Some development of its answers have also been explored too. We found it a quite interesting exercise. But please note {with some alarm} AI's concern with "Regulatory Authorities", "Policy" and "Policy Makers" - the modern "evils" of our times!!

Q 1) Given that in winter the UK still needs 60% of electricity demand provided by Natural Gas and Coal, how can we reduce demand to allow renewable's to provide a greater percentage

- There are several ways in which we can reduce the demand for natural gas and coal in the UK during the winter months to allow for renewable's to provide a greater percentage of our electricity supply:

- Energy efficiency: The most effective way to reduce energy demand is to improve the energy efficiency of buildings and appliances. This can be achieved through better insulation, more efficient heating and cooling systems, and more energy-efficient appliances. By reducing energy waste, we can lower our overall energy consumption and reduce our reliance on fossil fuels. {an agenda driven statement indeed - bad AI!}

- Demand-side management: This involves shifting energy use to times when renewable energy sources are available, such as during periods of high wind or sunshine. This can be achieved through time-of-use tariffs, which incentivise customers to use energy during off-peak hours when renewable energy is more abundant. {pricing strategies are not an ideal route - old age pensioners could die with this approach, frightened to turn on their boilers} bad, bad, AI

- Energy storage: Battery storage technology is rapidly advancing, and large-scale battery storage can help to smooth out the intermittent supply of renewable energy. This allows excess renewable energy to be stored for use when demand is high, reducing the need for natural gas and coal. {Please add alternative "storage solutions, eg. "pumped storage" as at Dinorwig Peak Lopping _ too much battery talk AI!}

- Smart grids: Smart grids can help to manage the supply and demand of energy more efficiently. By using advanced sensors and communications technology, smart grids can match energy demand with the available supply of renewable energy.

- More renewable energy generation: Of course, the ultimate solution is to increase the amount of renewable energy generation in the UK. This can be achieved through a combination of onshore and offshore wind, solar, and other renewable sources, such as hydro-power and geothermal. With more renewable energy generation, the need for natural gas and coal can be gradually phased out. We threw this statement straight back at AI, as no time scale aspects have been considered - its almost a "slogan" not information - but the "blame" here lies with those promoting this mis-information {generally at State level}

Q 2) "With more renewable energy generation, the need for natural gas and coal can be gradually phased out." Please critique this statement given the timescale involved to achieve these targets

Page 9 of 11